Research & Development

Explore our adhesive product development lab.

Our research & development team relies on state-of-the-art equipment to formulate new product offerings and solve unique industrial and construction challenges. Each of our R&D labs is fully staffed with trained personnel who use these tools to expedite development cycles, validate the quality of inbound raw materials and precisely control the specifications of our finished products. Our research and development capabilities are a key part of our extensive service offering. We are experts in adhesive product development.

Learn more about our technology below:

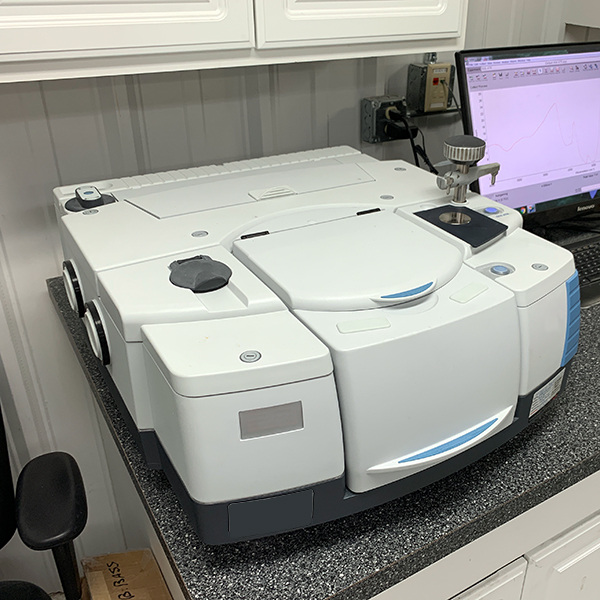

Spectrometer

What is it? Fourier-transform infrared spectroscopy (FTIR) is a technique used to obtain an infrared spectrum of absorption or emission of a solid, liquid or gas. An FTIR spectrometer simultaneously collects high-spectral-resolution data over a wide spectral range.

How do we use it? Primarily as the first step in analyzing our raw materials. Our expansive library of material analysis allows us validate the contents and quality of raw ingredients from our suppliers.

Rheometer

What is it? A Rotational or shear rheometer that measures the way in which a liquid, suspension or slurry flows in response to applied forces. It is used for those fluids which cannot be defined by a single value of viscosity.

How do we use it? Our products are formulated for use with various types of application equipment and methods that apply unique forces to the adhesive or sealant.Our unique chemistry results in products that exhibit non-newtonian properites, when subject to these forces.

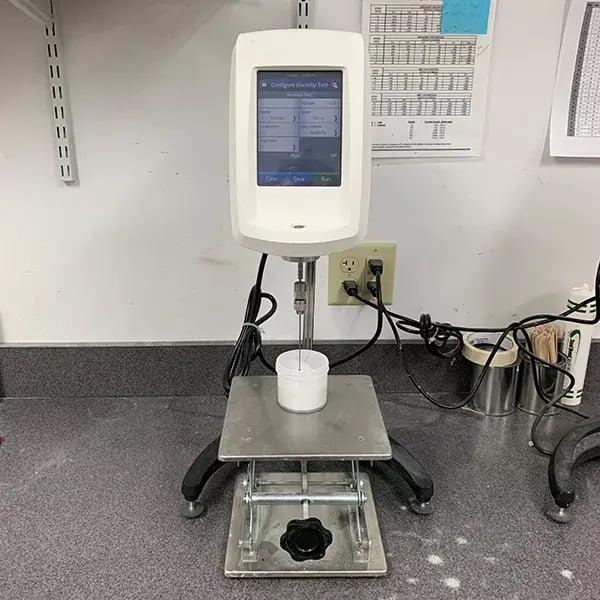

Viscometer

What is it? A device that measures the resistance to flow of a material in typical atmospheric conditions.

How do we use it? To establish a baseline of how our products will flow under shear and normal atmospheric conditions. This is especially relevant for new product developments that will be sprayed directly from a pail or drum or gunned from a cartridge.

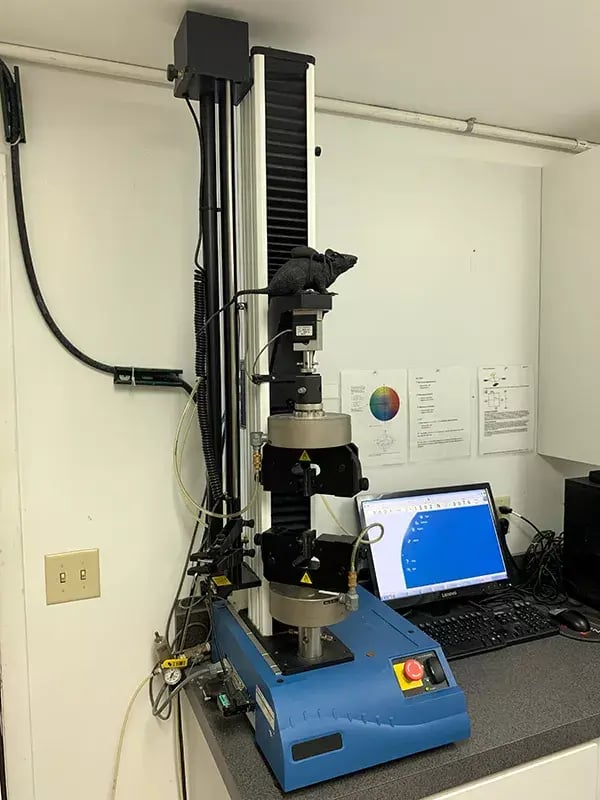

Instron

What is it? The Instron pushes or pulls on a sample asssembly and measures the stress applied over a given strain.

How do we use it? We use the instron to measure tensile strength, modulus of elasticity, elongation to break, peel strength and lap shear for new adhesive developments within very tight tolerances and to ASTM defined test methods.

Learn more about the mechanical properties of adhesives here…

Coulometric Titrator

What is it? A coulometric titrator is used to measure concentrations of moisture in a given material.

How do we use it? Many of our products use moisture from the atmosphere to cure or cross-link into their solid state. Our quality assurance team measures the moisture content of every batch that we produce to ensure that it will perform as specified when it reaches the point of application.

Semiworks Polymer Reactor

What is it? Polymerization chemistry is the process of reacting monomer molecules together in a chemical reaction to build polymer chains or three-dimensional networks.

How do we use it? As with many adhesives and sealants, polymers are the backbone of our technology. Our fully equipped semiworks polymer reactor allows us to test and scale the production of polymers, and gain deeper insights into our product developments and their performance attributes.

Accelerated Weathering Tester

What is it? To simulate outdoor weathering, the accelerated tester exposes materials to alternating cycles of UV light and moisture at controlled, elevated temperatures. It simulates the effects of sunlight using special fluorescent UV lamps. It simulates dew and rain with condensing humidity and/or water spray.

How do we use it?Our new products are on the cutting edge of sealing and adhesion technology and our customers need to have confidence that they will perform to their requirements over time.We use accelerated weathering tests to bring new technology to market faster than real-world testing would allow.

Hydraulic Airless Sprayer

What is it? This hydraulic airless sprayer is a high performance spray applicator that is used to apply a wide range of materials under pressure.

How do we use it? Our airless sprayer is used to refine formulations and determine optimal application techniques that maximize the efficiency and performance. This provides deeper insight into our adhesive product developments at their use point.

All of our equipment has been implemented to improve our ability to respond to customer’s needs, whether they are manufacturers in product assembly, adhesive or sealant distributors or a part of the construction industry.In addition to the equipment shown above, we many more specialized analysis tools that may be relevant to your industry.Please contact us for more information.

Recent Posts

Archives

- September 2025 (4)

- August 2024 (3)

- September 2024 (3)

- October 2024 (3)

- November 2024 (3)

- October 2025 (3)

- January 2019 (2)

- January 2025 (2)

- March 2025 (2)

- May 2025 (2)

- July 2025 (2)

- August 2025 (2)

- December 2025 (2)

- October 2015 (1)

- February 2019 (1)

- March 2019 (1)

- April 2019 (1)

- May 2019 (1)

- June 2019 (1)

- July 2019 (1)

- August 2019 (1)

- November 2019 (1)

- December 2024 (1)

- February 2025 (1)

- April 2025 (1)

- June 2025 (1)

- November 2025 (1)