Access Flooring

Concrete Sealers for Access Floor Systems

The concrete sealer is a critical component of any raised access flooring system. Treating the concrete aids in moisture protection and dust proofing, which are especially important for access floor air plenums. A general understanding of the different types of concrete sealers can ensure that your jobs are completed on time and to spec.

Types of Concrete Sealers

Concrete treatments can be divided into two distinct categories: penetrating densifiers and topical/film forming sealers. Learn more about the differences below.

Penetrating Sealers

Penetrating sealers typically strengthen, densify and dustproof concrete by sealing the pores of the concrete beneath the surface.Most penetrating sealers are silicate, siliconate, silane, or siloxane based.

Learn about Seal Bond MA 279 Concrete DensifierBenefits of penetrating sealers for access floor systems:

- Better pedestal bond: pedestal adhesives can still bond to the actual concrete surface.

- Lower cost: penetrating sealers are usually lower cost than their film-forming counterparts.

- Better internal moisture protection: densified concrete provides better protection from internal moisture.

Downsides of penetrating sealers for access floor systems:

- Chemical resistance: Penetrating sealers do not entirely protect the concrete from chemical exposure.

- Finished aesthetic: Penetrating sealers typically do not change the color or gloss of the concrete surface.

- Does not eliminate vapor transmission: Most penetrating sealers will not entirely eliminate vapor transmission.

Film Forming or Topical Sealers

Topical concrete sealers create a protective or decorative layer on the surface of the concrete. Most topical sealers are acrylic, epoxy or polyurethane based. Learn about Seal Bond MA 260 Acrylic Concrete Sealer or Seal Bond MA 200 High Build Epoxy Color Coat

Benefits of topical sealers for access floor systems:

- Chemical resistance: most film-forming sealers provide some level of protection from chemicals.

- Better external moisture protection: topical sealers typically provide a moisture proof layer to protect the underlying concrete.

- Appearance: film-forming sealers can modify the finished appearance of concrete color and shine.

Downsides of topical sealers for access floor systems:

- Higher cost: Topical sealers are generally more expensive than penetrating sealers.

- Prevent adhesive bond directly to concrete: which can potentially affect the strength of the access floor system.

- No substrate fortification: film-forming sealers do not affect the strength or density of the actual concrete.

Pedestal Adhesive & Sealer Compatability

Chemical compatibility is a measure of how stable a substance is when mixed or comes in contact with another substance. While Seal Bond 95 is chemically compatible with the sealers noted on this list when applied properly and once fully cured, Seal Bond makes no claims regarding the strength of the bond between the sealer and concrete. It is especially important that the sealant manufacturers mixing and curing instructions are followed correctly and in full before installing the pedestals.

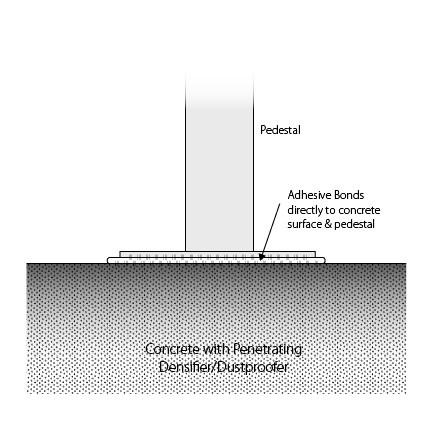

Generally, the pedestal adhesive will form a strong bond directly to the treated concrete, when using only a penetrating densifier or dustproofer.

When a topical/film-forming sealer is used, the overall strength of the pedestal installation will be determined by the strength of the bond between the pedestal adhesive and the strength of the bond between the sealer and the concrete.

Seal Bond always recommends that a field test (CISCA approved Overturning Moment Test) be performed by the appropriate personnel to determine that the performance of the system (concrete sealer, actual concrete, pedestal, and SB 95 Pedestal Adhesive) meets the engineering specifications and requirements for the project.

Recent Posts

Archives

- January 2026 (5)

- September 2025 (4)

- August 2024 (3)

- September 2024 (3)

- October 2024 (3)

- November 2024 (3)

- October 2025 (3)

- January 2019 (2)

- January 2025 (2)

- March 2025 (2)

- May 2025 (2)

- July 2025 (2)

- August 2025 (2)

- December 2025 (2)

- February 2026 (2)

- October 2015 (1)

- February 2019 (1)

- March 2019 (1)

- April 2019 (1)

- May 2019 (1)

- June 2019 (1)

- July 2019 (1)

- August 2019 (1)

- November 2019 (1)

- December 2024 (1)

- February 2025 (1)

- June 2025 (1)

- November 2025 (1)