Products

Industrial

Seal Bond® 114 – Industrial Sealant

Seal Bond® 114 is a multi-purpose, paintable, fast-curing one-component sealant. This product is moisture-curing and was developed for manufacturing and industrial applications. SB 114 delivers tough, elastic sealing performance, with excellent adhesion to steel, aluminum, wood, glass, and many plastics. SB 114 is solvent and isocyanate-free. It is for use on interior and exterior joints, including roofing, expansion walls, panel walls, window and door frames, and more. Request a free sample now!

Seal Bond® 105 High Performance Adhesive/Sealant

AVAILBLE NOW FROM THE FOLLOWING DISTRIBUTORS:

Seal Bond® 105 is a high-performance adhesive/sealant designed to provide enhanced adhesion for difficult bonding and sealing applications. SB 105 was developed for industrial applications requiring elasticity, durability and superior adhesion to many unprimed industrial substrates. Request a free sample now!

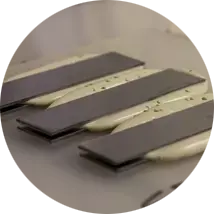

Seal Bond® 150 High Performance Adhesive

SB 150 HV is a one-component adhesive that provides rapid strength development, incredibly strong bonds and remains highly flexible after cure. SB 150 HV is designed for difficult bonding applications including adhesion to steel, aluminum, ceramics, Styrofoam®, coated metal, glass, wood, FRP, and many plastics (Acrylic, Polycarbonate, ABS, and PVC).

SB 150 HV is also suited for many applications requiring adhesion to concrete and cementitious building materials. SB 150 HV is based on a unique polymer system that will cure at temperatures as low as 13º F.