Raised Access Flooring

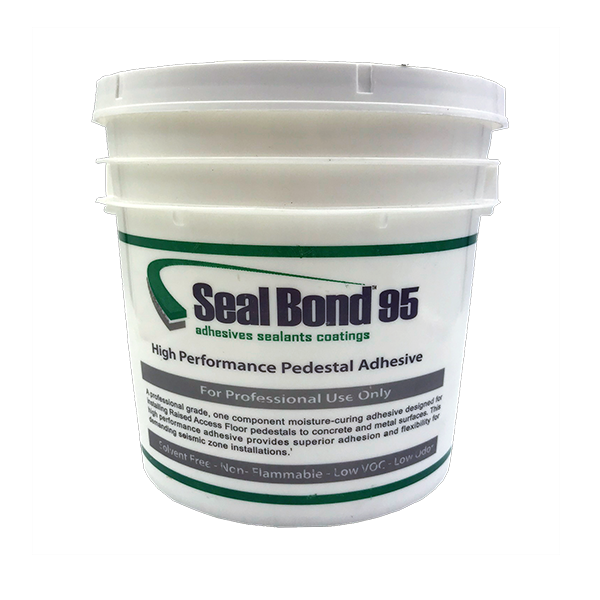

Seal Bond has been engineering and manufacturing high performing pedestal adhesives for nearly two decades. Our expanded product lines are designed to create flawless installations that exceed industry standards and reduce installation costs.

Raised Access Flooring Brochure List of compatible concrete sealers FAQs